Getting good, reliable measurements is super important in lots of areas, and when it comes to pressure, a high-precision pressure sensor is often the way to go. These gadgets are designed to give you really exact readings, which can make a big difference in everything from industrial controls to scientific experiments. But getting the most out of them isn’t just about plugging them in. You gotta know how they work, what can mess with their readings, and how to keep them running right. This article will walk you through the basics, helping you understand these sensors better so you can use them effectively.

Key Takeaways

- High-precision pressure sensors are all about giving you very exact pressure readings, which is important for many different uses.

- Things like temperature, how sensitive the sensor is, and how well it was made can really change how accurate your readings are.

- To make sure your sensor is working right, you need to test it often and make sure it’s calibrated correctly using a good standard.

- Keeping your sensor reliable means regular check-ups, protecting it from bad environments, and watching out for any long-term changes in its performance.

- There are smart ways to make your sensors even better, like fixing temperature problems and making sure the signal is clear and strong.

Understanding High-Precision Pressure Sensor Fundamentals

Defining High-Precision Pressure Sensor Accuracy

Okay, so what is accuracy when we’re talking about these sensors? It’s basically how close the sensor’s reading is to the actual, true pressure value. Think of it like throwing darts – if you’re accurate, your darts land close to the bullseye. In the sensor world, a sensor with high accuracy will give you readings that are very close to the real pressure. Factors like calibration and manufacturing quality really affect pressure sensor accuracy.

Defining High-Precision Pressure Sensor Precision

Now, precision is a little different than accuracy. Precision is all about repeatability. A precise sensor will give you almost the same reading every time you measure the same pressure, even if that reading isn’t perfectly accurate. Imagine shooting a group of darts that are all clustered together, but far from the bullseye. That’s high precision, low accuracy. Precision is affected by things like sensor sensitivity and noise.

The Relationship Between Precision and Accuracy

So, how do precision and accuracy relate? Well, ideally, you want both! A sensor that’s both precise and accurate will give you readings that are consistently close to the true value. But in the real world, there’s often a trade-off. You might have a sensor that’s very precise but consistently off by a small amount (inaccurate). Or, you might have a sensor that’s accurate on average, but the readings vary a lot (imprecise). Here’s a few things to keep in mind:

- High accuracy usually implies good precision, but not always.

- High precision doesn’t guarantee accuracy.

- Calibration can improve accuracy, but it won’t necessarily improve precision.

It’s important to understand the difference between accuracy and precision when choosing a pressure sensor for a specific application. Depending on your needs, you might prioritize one over the other. For example, in some applications, consistency is more important than absolute accuracy, while in others, the opposite is true.

Working Principles of High-Precision Pressure Sensors

Alright, let’s talk about how these fancy high-precision pressure sensors actually work. It’s not all magic; there’s some pretty cool engineering involved. Basically, we’re converting pressure into something we can measure electrically. There are a few different ways to do this, each with its own strengths and weaknesses. It’s important to understand these principles to really get the most out of your sensors.

Strain Gauge Based High-Precision Pressure Sensors

Strain gauges are a pretty common way to measure pressure. These sensors use the principle that a material’s electrical resistance changes when it’s stretched or compressed. Imagine a tiny wire glued to a surface that bends under pressure. As the surface bends, the wire stretches (or compresses), and its resistance changes. We can measure this change in resistance to figure out how much pressure is being applied. These are often arranged in a Wheatstone bridge configuration for increased sensitivity and temperature compensation. You’ll find these in a lot of digital air pressure sensors because they’re relatively simple and reliable.

Diaphragm and Can-Type Designs for High-Precision Pressure Sensors

Diaphragm and can-type designs are all about using a physical structure to translate pressure into a measurable displacement. A diaphragm is basically a thin, flexible membrane that deflects when pressure is applied. The amount of deflection is proportional to the pressure. A can-type design is similar, but it uses a sealed can that deforms under pressure. This deformation can then be measured using various techniques, including strain gauges or capacitive sensors. These designs are often used for higher pressure ranges because they can be made more robust. Here’s a quick comparison:

| Feature | Diaphragm Design | Can-Type Design |

|---|---|---|

| Pressure Range | Lower to Medium | Medium to High |

| Sensitivity | Higher | Lower |

| Robustness | Lower | Higher |

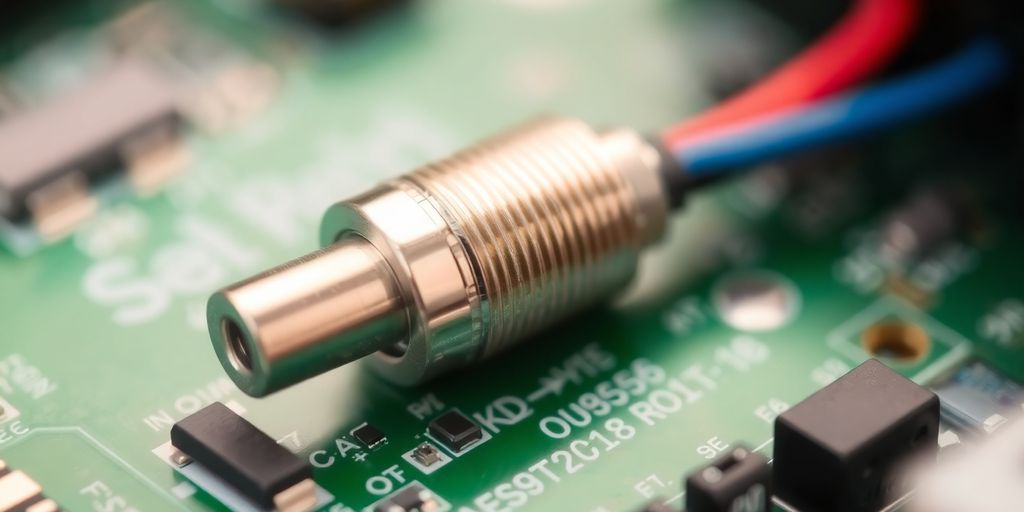

Electrical Connection Methods for High-Precision Pressure Sensors

How do we get the signal from the sensor to our measurement system? Well, there are a few common ways to make the electrical connection. Here are some of the most common methods:

- Wire Bonding: Tiny wires are bonded directly to the sensor element and then connected to external pins or pads. This is common for small sensors.

- Soldering: Larger components or wires can be soldered directly to the sensor. This provides a more robust connection than wire bonding.

- Connectors: Some sensors use connectors to make it easy to plug and unplug them. This is useful for applications where the sensor needs to be replaced frequently.

Choosing the right electrical connection method is important for ensuring reliable signal transmission and minimizing noise. You need to consider things like the size of the sensor, the operating environment, and the required level of robustness.

Factors Affecting High-Precision Pressure Sensor Performance

Impact of Temperature on High-Precision Pressure Sensor Readings

Temperature changes can really mess with how well a high-precision pressure sensor works. It’s just a fact. Temperature affects the sensor’s materials, causing them to expand or contract, which throws off the readings. It’s like trying to measure something with a rubber ruler – the hotter it gets, the more it stretches, and the less accurate your measurement becomes. Environmental factors like these can cause shifts in zero and span output.

Here’s a quick rundown of what temperature can do:

- Changes the sensor’s sensitivity.

- Causes zero drift (the output reading when there’s no pressure).

- Affects the overall accuracy of the measurement.

To deal with this, many high-precision sensors have built-in temperature compensation. This involves using a temperature sensor inside the pressure sensor to correct for temperature-related errors. It’s a clever way to keep things accurate, even when the temperature is all over the place.

Sensor Sensitivity and Its Role in High-Precision Pressure Measurement

Sensor sensitivity is how much the sensor’s output changes for a given change in pressure. A more sensitive sensor will produce a bigger signal change for a small pressure change, which can lead to better precision. Think of it like this: if you’re trying to weigh something tiny on a regular scale, you might not see any movement. But if you use a super-sensitive scale, you’ll see even the smallest weight changes.

Here’s why sensitivity matters:

- Higher sensitivity means you can detect smaller pressure differences.

- It improves the signal-to-noise ratio, making the signal clearer.

- It allows for more precise measurements, especially in applications where pressure changes are minimal.

Manufacturing Quality and Its Influence on High-Precision Pressure Sensor Precision

The quality of manufacturing plays a huge role in how precise a pressure sensor is. It’s not just about the design; it’s about how well that design is executed. If the components aren’t made to tight tolerances, or if the assembly process is sloppy, the sensor’s performance will suffer. Think of it like building a race car – if the parts aren’t perfectly aligned and assembled, it won’t perform as expected. Selecting reputable manufacturers is key.

Here are some key aspects of manufacturing that affect precision:

- Component tolerances: How closely the parts match the design specifications.

- Calibration procedures: How accurately the sensor is calibrated during manufacturing.

- Material stability: How well the materials hold up over time and under different conditions.

| Manufacturing Factor | Impact on Precision nobody wants to see that. It’s like buying a cheap tool set – it might look okay at first, but it won’t hold up under pressure.

Evaluating High-Precision Pressure Sensor Accuracy and Precision

Interpreting Accuracy and Precision Data for High-Precision Pressure Sensors

When you’re staring at a datasheet for a high-precision pressure sensor, it’s easy to get lost in the numbers. But understanding what those numbers actually mean is super important. Accuracy tells you how close the sensor’s reading is to the real pressure value, while precision tells you how consistent the readings are when measuring the same pressure repeatedly.

Think of it like this:

- Accuracy: Hitting the bullseye on a dartboard.

- Precision: Consistently hitting the same spot on the dartboard, even if it’s not the bullseye.

Ideally, you want both, but sometimes you have to trade one for the other depending on the application. If you’re monitoring something critical, like the pressure in a medical device, accuracy is paramount. For other applications, consistency might be more important. For example, NovaSensor provides high-accuracy pressure sensors for medical, automotive, and industrial applications, meeting the demand for precision in various designs.

It’s important to remember that accuracy and precision are often specified under certain conditions. Temperature, pressure range, and other factors can affect these values, so always check the fine print.

Tips to Test and Validate High-Precision Pressure Sensor Accuracy

Okay, so you’ve got a fancy new high-precision pressure sensor. How do you know if it’s actually living up to its claims? Here’s a simple checklist:

- Use a Calibration Standard: This is a device with known accuracy that you’ll use as a reference. Make sure its accuracy is significantly better than the sensor you’re testing.

- Test Across the Range: Don’t just test at one pressure point. Test the sensor across its entire operating range to see how it performs at different pressures.

- Take Multiple Readings: Take several readings at each pressure point to assess the sensor’s precision. Calculate the mean and standard deviation of the readings.

- Document Everything: Keep detailed records of your testing process, including the date, time, temperature, pressure points, and readings. This will help you track the sensor’s performance over time.

Selecting a Calibration Standard for High-Precision Pressure Sensors

Choosing the right calibration standard is key to getting reliable results. Here are some things to keep in mind:

- Accuracy: The standard should be significantly more accurate than the sensor you’re testing. A good rule of thumb is to use a standard that’s at least four times more accurate.

- Traceability: The standard should be traceable to a national or international standard, such as NIST in the United States. This ensures that the standard’s accuracy is verifiable.

- Stability: The standard should be stable over time and temperature. This means that its accuracy shouldn’t drift significantly over time or with changes in temperature.

Here’s a table summarizing the key considerations:

| Factor | Importance Choosing the right calibration standard is a critical step in ensuring the accuracy and reliability of high-precision pressure sensors. It’s not just about picking any random device; it’s about selecting one that meets specific criteria to provide a trustworthy reference for comparison. By carefully considering factors like accuracy, traceability, and stability, you can ensure that your calibration process yields meaningful results and that your pressure sensors are performing as expected. This attention to detail is essential for maintaining the integrity of your measurements and the overall reliability of your systems.

Maintaining High-Precision Pressure Sensor Reliability

Regular Calibration and Maintenance for High-Precision Pressure Sensors

Okay, so you’ve got this fancy high-precision pressure sensor. Great! But like any piece of equipment, it needs some TLC to keep it working right. Regular calibration is super important. Think of it like tuning a musical instrument; if you don’t, things will sound off eventually. Calibration makes sure the sensor’s output matches a known standard. Over time, sensors can drift, and calibration corrects for that. Maintenance involves checking for physical damage, loose connections, and keeping things clean. A little effort here can save you a lot of headaches later.

- Check sensor connections regularly.

- Clean the sensor housing to prevent buildup.

- Schedule routine calibrations.

Neglecting regular maintenance can lead to inaccurate readings and premature sensor failure. It’s an investment in the long-term reliability of your measurements.

Environmental Protection for High-Precision Pressure Sensors

These sensors are sensitive little guys. The environment they’re in can really mess with their performance. Things like temperature swings, humidity, vibration, and even electromagnetic interference can throw off readings. You need to protect them! Consider using enclosures to shield them from the elements. Temperature control might be necessary in some cases. Also, be mindful of where you place the sensor; keep it away from sources of vibration or strong electromagnetic fields. Basically, treat it like it’s allergic to everything.

- Use protective enclosures.

- Control temperature and humidity.

- Minimize vibration and electromagnetic interference.

Monitoring Long-Term Stability and Drift in High-Precision Pressure Sensors

Even with regular calibration, sensors can still drift over time. It’s just a fact of life. Monitoring long-term stability is key to catching these subtle changes. Keep a record of calibration data and look for trends. If you see the sensor consistently drifting in one direction, it might be a sign of a bigger problem. Some sensors have built-in diagnostics that can help with this. Pay attention to the manufacturer’s specifications for long-term drift; they’ll usually give you a drift rate (like ±0.1% per year). If the drift exceeds that, it’s time for a closer look.

Here’s a simple table to illustrate drift monitoring:

| Date | Reading (at known pressure) | Drift from Initial | Action Needed? |

|---|---|---|---|

| 2024-07-02 | 100.0 PSI | 0.0 PSI | No |

| 2024-10-02 | 100.1 PSI | 0.1 PSI | No |

| 2025-01-02 | 100.2 PSI | 0.2 PSI | No |

| 2025-04-02 | 100.4 PSI | 0.4 PSI | Yes (Investigate) |

Advanced Techniques for High-Precision Pressure Measurement

Temperature Compensation Techniques for High-Precision Pressure Sensors

Real-world sensors drift as the temperature swings. To counter this, you can use on-board temperature sensors and feed their readings into a correction algorithm. In many aerospace systems, low-drift precision pressure transducers rely on a two-step process:

- Characterize the sensor’s output at several temperatures (e.g., –20 °C, 0 °C, 25 °C, 50 °C, 80 °C).

- Fit a polynomial or spline curve to map temperature to offset and span corrections.

- Store the coefficients in the sensor’s firmware or in your data-acquisition system.

| Temperature (°C) | Offset Correction (mV) | Span Correction (%) |

|---|---|---|

| –20 | –1.2 | 0.8 |

| 0 | –0.5 | 0.3 |

| 25 | 0 | 0 |

| 50 | +0.4 | –0.2 |

| 80 | +1.0 | –0.5 |

Effective Signal Conditioning for High-Precision Pressure Sensors

A stable signal path matters as much as the sensor itself. Start with a clean bridge excitation and end with a low-noise amplifier:

- Use a precision regulator or reference to power the bridge.

- Choose op-amps with low offset and low drift for your first amplification stage.

- Add anti-aliasing filters before your ADC to remove unwanted high-frequency noise.

Fine-tune gain stages to match your ADC’s full-scale range, and you’ll squeeze more resolution out of the same sensor. Watch out for bridge excitation variations—they show up directly in your readings.

Keep an eye on each stage of your signal chain. A tiny fault in the first amplifier can ruin the entire measurement.

Minimizing Noise and Maximizing Signal-to-Noise Ratio

Noise sources hide everywhere: wiring, environment, electronics. Without good noise control, even the best sensors can give erratic readings. Try these:

- Use twisted-pair or coaxial cables, and ground only at one end to avoid loops.

- Enclose sensitive circuits in metal shields tied to ground.

- Employ differential inputs on your ADC to cancel common-mode noise.

- Implement digital filtering (e.g., moving average, Kalman) or oversampling to boost effective resolution.

| Technique | Typical SNR Gain (dB) |

|---|---|

| Shielded cable | +10 |

| Differential measurement | +12 |

| Digital oversampling (×4 samples) | +6 |

Conclusion

So, that’s the deal with high-precision pressure sensors. Getting them to work just right isn’t always easy, but it’s super important for a lot of jobs. We’ve talked about how things like temperature can mess with readings and why picking good sensors from good companies matters. Remember, checking them regularly and keeping them safe from the environment helps a lot. If you do all that, you’ll get good, steady measurements, and that’s what we’re all aiming for, right?

Frequently Asked Questions

What exactly are high-precision pressure sensors?

High-precision pressure sensors are super accurate tools that measure pressure. They’re designed to give you very exact readings, much more precise than regular pressure sensors. Think of them like a super-sensitive scale for pressure.

What’s the difference between ‘accuracy’ and ‘precision’ when talking about these sensors?

Accuracy means how close your measurement is to the real, true value. Precision means how close your measurements are to each other, even if they’re all a bit off from the true value. For example, if you aim at a target, accuracy is hitting the bullseye, and precision is hitting the same spot every time, even if it’s not the bullseye.

How does temperature affect how well these sensors measure pressure?

Temperature can really mess with how these sensors work. When it gets hotter or colder, the sensor’s parts can change slightly, making the readings less accurate. That’s why many high-precision sensors have special features to adjust for temperature changes.

Why is it so important to calibrate these sensors often?

Calibration is like fine-tuning your sensor. You compare its readings to a known, super-accurate standard. If your sensor is off, you adjust it so it reads correctly. This needs to be done regularly because sensors can drift over time, meaning their readings slowly become less accurate.

What can I do to make sure my high-precision pressure sensor lasts a long time and stays reliable?

You need to protect these sensors from harsh environments. This means keeping them safe from extreme temperatures, too much moisture, strong vibrations, and even electrical interference. Good protection helps them last longer and keep giving accurate readings.

How can I get the clearest and most accurate readings from my sensor, especially if there’s a lot of interference?

There are smart ways to make the sensor’s signal clearer and reduce unwanted noise. This includes using special electronic circuits to clean up the signal and making sure the sensor is installed in a way that minimizes interference. These techniques help you get the most accurate reading possible.