As one of the greatest inventions of humanity in the 20th century, lasers have been widely integrated into multiple fields such as industrial manufacturing, medical cosmetology, scientific research, and consumer electronics. However, the high-energy characteristics of lasers also make them a “double-edged sword”—improper use may cause irreversible damage to the human body. To standardize the safety criteria for laser products, an international laser classification system has been established. Through quantitative evaluation of parameters such as laser wavelength, energy output, and exposure risk, lasers are divided into different safety classes, with targeted protection strategies formulated accordingly. This article systematically analyzes the technical details, hazard mechanisms, and protective measures of laser classification based on the International Electrotechnical Commission (IEC) 60825-1 standard and the U.S. Food and Drug Administration (FDA)’s CDRH standard, providing a comprehensive safety guide for laser-related professionals and the public.

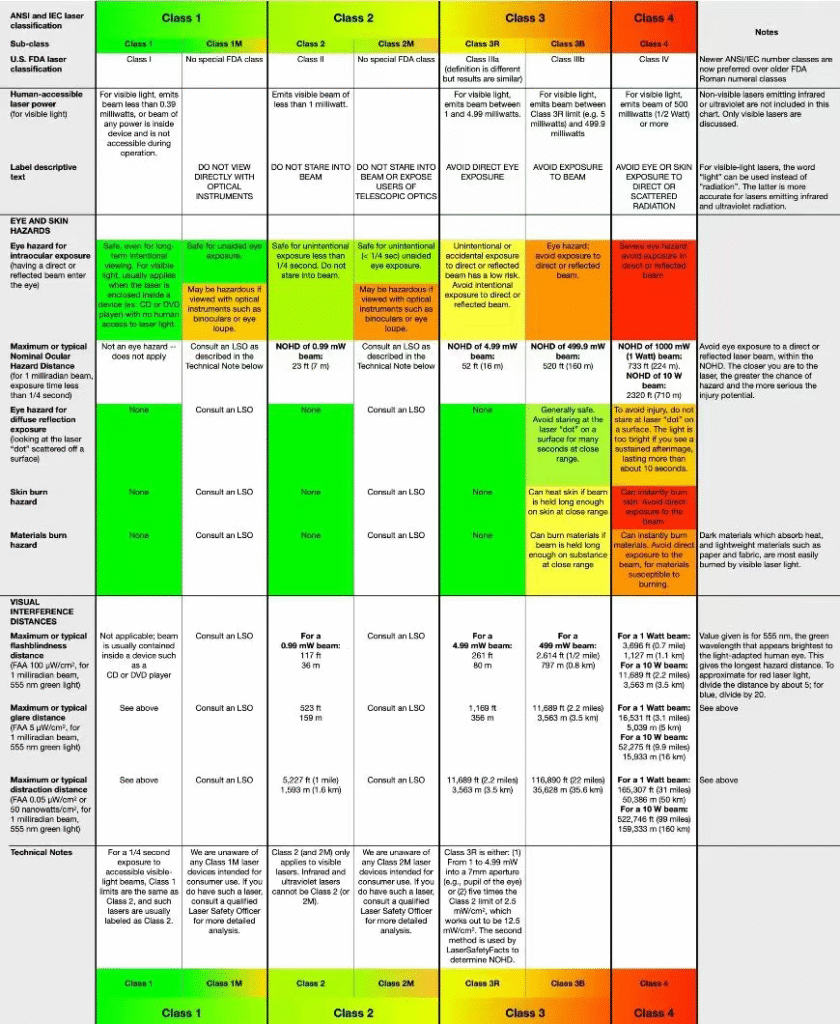

| evel | Classification | Wavelength Range | Power/Energy Limitations | Hazard Characteristics | Protection Requirements |

|---|---|---|---|---|---|

| Class 1 | No Risk Level | Full wavelength range | – Continuous Wave (CW): Visible light < 0.39mW, equivalent power of other wavelengths ≤ 1mW – Pulse laser: Single – pulse energy ≤ 20μJ (visible light) | – Eyes: No risk from or – Skin: No thermal damage risk | – No special protection required – Equipment needs to be sealed to ensure no laser leakage (such as laser printers) |

| Class 1M | Low Risk (Collimated Light) | Full wavelength range | – Power same as Class 1, but the beam divergence is extremely small (such as laser rangefinders) | – Safe for ,but observing through optical instruments like telescopes may focus the beam, increasing the risk of retinal damage | – Prohibit the use of optical instruments for observation – Equipment marked with “Prohibit Observation with Optical Instruments” warning |

| Class 2 | Low – Risk Visible Light | 400 – 700nm (visible light) | – Continuous power: 0.39mW < P ≤ 1mW – Based on “blink reflex” (0.25 seconds), single – exposure energy does not exceed the retinal damage threshold | – Bare – eye direct vision: Blink reflex can protect, but intentional staring may cause retinal injury – Skin: No risk | – Avoid long – term staring at the beam – Children need adult supervision – Equipment marked with “Avoid Direct Vision” warning |

| Class 2M | Low – Risk Visible Light (Collimated Light) | 400 – 700nm (visible light) | – Power same as Class 2, but the beam divergence is extremely small (such as laser barcode scanners) | – Safe for ,but observing through optical instruments has a risk higher than Class 3B | – Strictly prohibit observation through instruments like telescopes and microscopes – Equipment marked with “Prohibit Observation with Optical Instruments” warning |

| Class 3R | Medium Risk | Full wavelength range | – Visible light continuous wave: 1mW < P ≤ 5mW – Invisible light: Equivalent power ≤ 5mW (such as 1064nm infrared laser, average power ≤ 25mW allowed) | – Bare – eye direct vision: Short – term exposure (< 0.25 seconds) is basically safe, continuous exposure may cause damage – Skin: Long – term irradiation may cause heat sensation | – Prohibit direct vision of the beam, maintain a safe distance (> 1 meter) – Equipment marked with “Class 3R Laser Hazard” warning |

| Class 3B | High Risk | Full wavelength range | – Continuous wave: Visible light ≤ 0.5W, infrared/ultraviolet ≤ 10W – Pulse laser: Single – pulse energy ≤ 500mJ, average power ≤ 0.5W | – Eyes: Direct/reflected light can cause immediate blindness, can also cause slow retinal injury – Skin: Long – term direct irradiation may cause burns | – Wear OD4+ protective goggles (select models according to wavelength) – Equipment with closed optical paths, set up interlock devices |

| Class 4 | Extremely High Risk | Full wavelength range | – Continuous wave: Visible light > 0.5W, infrared/ultraviolet > 10W – Pulse laser: Single – pulse energy > 500mJ, average power > 0.5W | – Eyes: Immediate blindness, may also cause injury – Skin: Instantaneous vaporization/carbonization, may ignite flammable materials | – Wear OD8+ protective goggles, full – body laser protection – Fully enclosed optical paths, set up double fences and monitoring systems |

Key Explanations in the Table:

- Correlation Between Wavelength and Power

◦ Visible light (400–700 nm) has strict power limitations due to the retinal focusing effect (e.g., Class 2 ≤1 mW);

◦ Infrared/ultraviolet lasers have higher power thresholds due to different penetration depths (e.g., Class 3B 1064 nm infrared lasers allow an average power ≤10 W). - Nature of M-Class Classification

◦ The risk of Class 1M/2M stems from beam collimation: direct naked-eye viewing scatters energy due to the small beam diameter; however, focusing through optical instruments can increase the energy received by the pupil by hundreds of times, upgrading the risk. - Special Considerations for Pulsed Lasers

◦ The hazard of pulsed lasers is determined by both single-pulse energy and peak power. For example, a laser with a 10 Hz repetition frequency and 100 mJ single-pulse energy has an average power of only 1 W (Class 3B), but its peak power can reach 10 kW, with instantaneous energy sufficient to penetrate the retina. - Targeted Protective Equipment

◦ Safety goggles: Models must be selected according to wavelength (e.g., “OD4+” for visible light, “OD6+” for infrared, and custom “OD8+” goggles for Class 4);

◦ Protective clothing: Class 4 requires full-body laser-resistant suits (inner layer flame-retardant, outer layer laser-reflective) to prevent direct exposure of bare skin to beams. - Differences Between International Standards

◦ While IEC 60825-1 and FDA 21 CFR 1040.10 share core classification logic, some parameter thresholds differ slightly (e.g., FDA’s Class IIIa corresponds to IEC’s Class 3R).

Typical Application Scenarios:

• Class 1: CD/DVD optical drives, laser lidar in household robotic vacuum cleaners;

• Class 2: Educational laser pointers (power ≤1 mW), stage lighting;

• Class 3B: Medical laser scalpels (low-power mode), green lasers for scientific research;

• Class 4: Industrial laser cutters, military laser weapons.

Through the above table, users can quickly identify the risk class of laser products and implement corresponding protective measures to ensure safe operation.

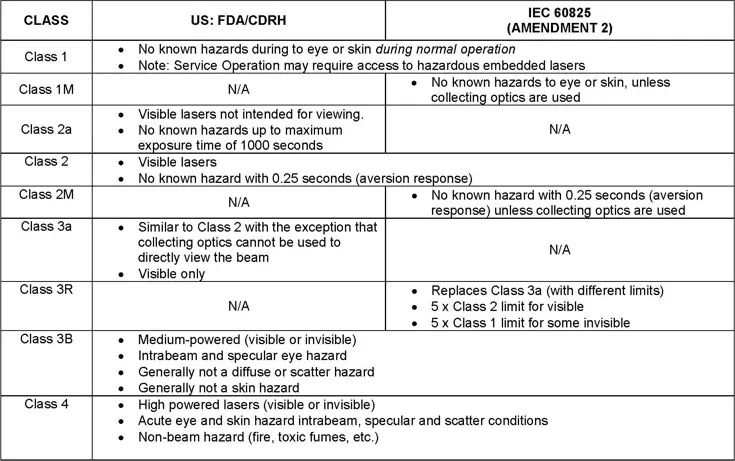

I. Core Standards and Classification Framework of Laser Classification Systems

1.1 Overview of International Mainstream Classification Standards

The most widely used laser safety classification standard worldwide is the IEC 60825-1 Laser Product Safety – Part 1: Equipment Classification, Requirements, and User Guidelines (Latest Edition: 3rd Edition published in 2014). This standard is adopted by regions such as the European Union and China. In the United States, the FDA’s 21 CFR Part 1040.10 (CDRH Standard) is utilized. While both standards share fundamentally consistent core classification principles, there are minor discrepancies in some parameter thresholds. Additionally, standards such as Japan’s JIS C 6802 and the International Organization for Standardization’s ISO 15004 have been developed based on the IEC framework, creating a globally unified laser safety assessment system.

1.2 Core Classification Parameters: Wavelength, Energy, and Exposure Time

The hazard level of lasers primarily depends on three key factors:

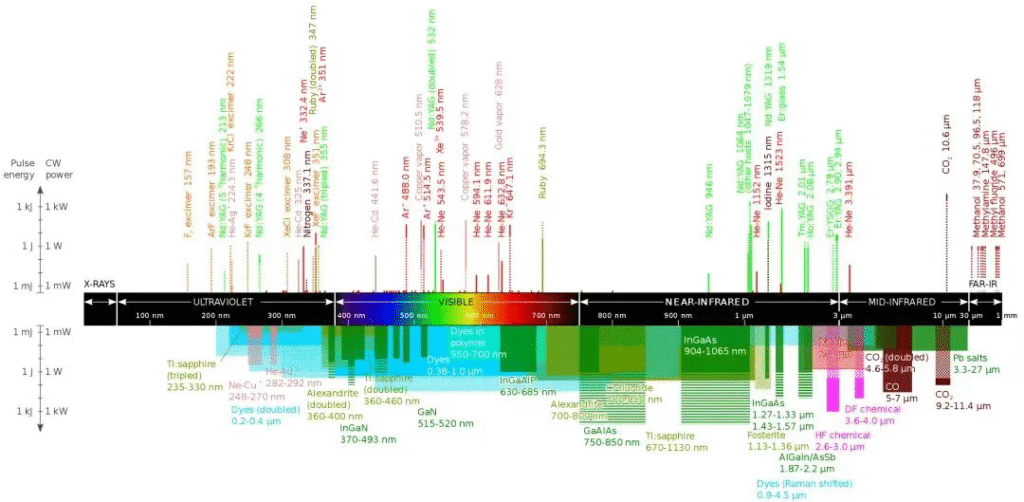

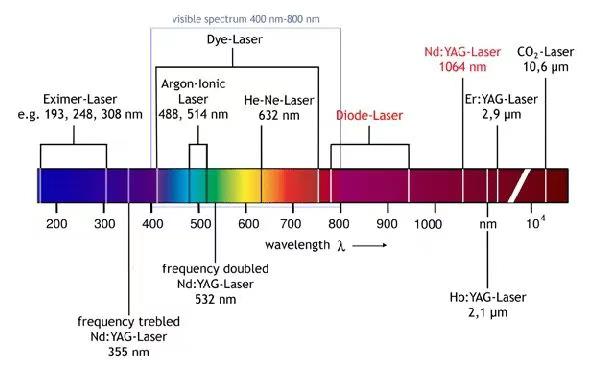

Wavelength (λ): Lasers with different wavelengths have varying penetration depths and absorption characteristics in biological tissues.

Ultraviolet Band (λ < 400 nm): This wavelength range is primarily absorbed by the cornea and lens, making it prone to causing conditions such as keratitis and cataracts.

Visible Light Band (400 nm ≤ λ ≤ 700 nm): This range can reach the retina directly, and concentrated energy may potentially damage photoreceptor cells, leading to burns.

Infrared Band (λ > 700 nm):

Long-Wave Infrared (λ > 1400 nm): This wavelength is mainly absorbed by the skin and cornea.

Mid-Infrared (700 nm < λ ≤ 1400 nm): This range can penetrate the cornea but is absorbed by the lens, which can result in thermal damage.

Output Power/Energy: Continuous-wave (CW) lasers are measured in watts (W), while pulsed lasers are evaluated based on single-pulse energy (joules, J) or average power (W). Higher energy levels increase the risk of damage.

Exposure Time (t): The length of time a person is exposed to laser light directly affects the cumulative damage that can occur. For example, the retina has a specific tolerance for pulsed lasers for up to 0.25 seconds, but the risk of damage increases significantly beyond this duration.

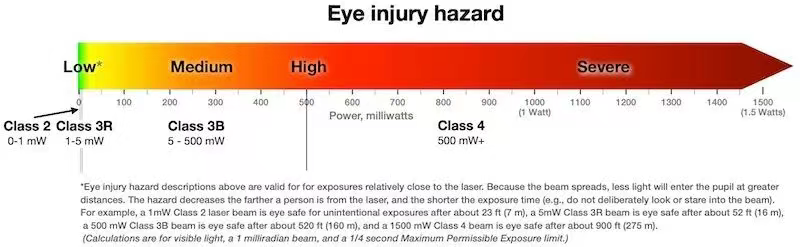

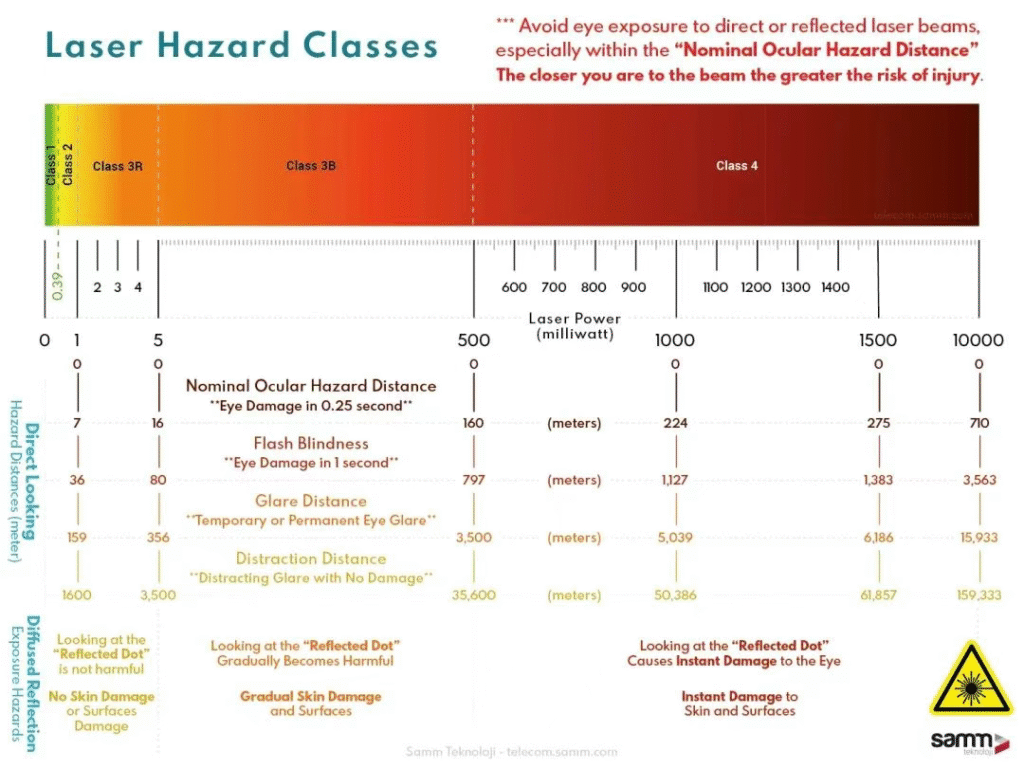

1.3 Classification Framework: Risk Gradient from Class 1 to Class 4

Lasers are categorized into five main classes based on their risk levels: Class 1 (low risk), Class 2 (low risk, visible light), Class 3A (moderate risk), Class 3B (high risk), and Class 4 (extremely high risk). Additionally, there are subcategories such as Class 1M and Class 2M that account for beam divergence, creating a comprehensive risk classification system (refer to Table 1).

II. Technical Parameters, Hazard Characteristics, and Protection Key Points for Each Laser Class

2.1 Class 1: Non-Hazardous Class

2.1.1 Classification Criteria

• Core Definition: Lasers that do not cause harm even when directly viewing the beam under normal operating conditions.

Parameter Limits:

Total energy per time must comply with exposure thresholds (e.g., for a 1064 nm infrared laser, average power must be ≤5 mW).

Continuous Wave (CW):

Full wavelength range.

Power must be ≤0.4 mW for the visible light band (400–700 nm).

For other wavelengths, the equivalent power must be ≤1 mW, calculated using a wavelength-weighted function.

Pulsed Lasers:

Single-pulse energy must be ≤20 μJ for visible light.

• Typical Applications: Laser printers (with enclosed optical paths), CD/DVD optical drives, most consumer-grade laser rangefinders (e.g., laser lidar in household robotic vacuum cleaners).

2.1.2 Hazard Characteristics

Skin: The energy density is extremely low; there is no risk of thermal damage.

Eyes: The reflection, both direct and diffuse, does not exceed the physiological tolerance threshold of the eye; there is no risk of photic injury.

II. Technical Parameters, Hazard Characteristics, and Protection Key Points for Each Laser Class

2.1 Class 1: Non-Hazardous Class

2.1.1 Classification Criteria

• Core Definition: Lasers that do not cause harm even when directly viewing the beam under normal operating conditions.

• Parameter Limits:

◦ Continuous Wave (CW): Full wavelength range, power ≤0.4 mW (visible light band, 400–700 nm); for other wavelengths, equivalent power ≤1 mW calculated via wavelength-weighted function.

◦ Pulsed Lasers: Single-pulse energy ≤20 μJ (visible light), or total energy/time complies with exposure thresholds (e.g., 1064 nm infrared laser, average power ≤5 mW).

• Typical Applications: Laser printers (with enclosed optical paths), CD/DVD optical drives, most consumer-grade laser rangefinders (e.g., laser lidar in household robotic vacuum cleaners).

2.1.2 Hazard Characteristics

• Eyes: Neither direct nor diffuse reflection exceeds the eye’s physiological tolerance threshold; no risk of photic injury.

• Skin: Extremely low energy density; no risk of thermal damage.

2.1.3 Protection Requirements

• No special protection needed: No goggles or protective clothing required; devices can be used directly by the public.

• Safety design: Equipment must pass sealing tests to ensure no accidental beam exposure (e.g., laser auto-shuts off when the optical drive is opened).

2.2 Class 2: Low-Risk Visible Light Lasers (Including Class 2M)

2.2.1 Classification Criteria

• Scope of application: Only applicable to continuous-wave lasers in the visible light band (400–700 nm).

• Parameter limits:

◦ Continuous power: 0.4 mW < P ≤ 1 mW;

◦ Exposure time threshold: Based on the “blink reflex” (≈0.25 seconds) to ensure single-exposure energy does not exceed retinal damage thresholds.

• Class 2M: Low beam divergence (e.g., collimated lasers). Safe for direct naked-eye viewing, but observing through optical instruments (telescopes, microscopes) may focus the beam, increasing retinal risk.

2.2.2 Hazard Characteristics

• Eyes:

◦ Direct naked-eye viewing: Short exposure (≤0.25 seconds due to blink reflex) generally causes no damage, but intentional prolonged staring may exceed tolerance thresholds, leading to retinal 光斑灼伤 (retinal spot burns, especially risky for curious children).

◦ Class 2M: When observed through optical instruments, beam focusing may increase equivalent power beyond Class 1M safety thresholds; caution is required.

• Skin: Low energy density; no significant thermal damage risk.

2.2.3 Typical Applications

• Class 2: Low-power laser pointers (power ≤1 mW, common in educational demonstrations), some stage lighting (visible pulsed lasers with compliant average power).

• Class 2M: Supermarket barcode scanners (collimated red lasers), laser levelers (low-power visible light, moderately concentrated beams).

2.2.4 Protection Requirements

• Personal protection:

◦ Avoid intentional staring at beams; children must use under adult supervision.

◦ Class 2M devices: Prohibit observation through optical instruments; label with “Do Not Observe Through Optical Instruments” warnings.

• Equipment design:

◦ Laser pointers must comply with power limits and be non-dismountable (prevent user modification for higher power).

◦ Clearly label Class 2 safety signs with “Avoid Prolonged Direct Viewing.”

2.3 Class 3A: Moderate-Risk Lasers (Including Class 3A M)

2.3.1 Classification Criteria

• Parameter range:

◦ Visible continuous wave: 1 mW < P ≤ 5 mW;

◦ Non-visible (UV/infrared): Equivalent power ≤5 mW via wavelength weighting (e.g., 1064 nm infrared allows average power ≤25 mW due to retinal insensitivity to infrared);

◦ Class 3A M: Visible collimated beams with low naked-eye risk, but optical instrument observation may exceed Class 2M thresholds.

2.3.2 Hazard Characteristics

• **Eyes:**

◦ Direct viewing: Short exposure (≤0.25 seconds) is generally safe due to blink reflex, but prolonged exposure (>1 second) may cause retinal photochemical damage (visible light) or thermal damage (IR/UV).

◦ Diffuse reflection: Low energy, generally safe, but diffuse reflection of Class 3A M collimated beams may still focus (e.g., via mirrored surfaces).

• Skin: Prolonged irradiation (minutes+) may cause mild thermal sensation but typically no burns.

2.3.3 Typical Applications

• Class 3A: High-power laser pointers (2–5 mW, some non-compliant products may exceed limits), low-power visible laboratory lasers (e.g., helium-neon lasers for demonstrations).

• Class 3A M: Medical low-power laser physiotherapy devices (visible collimated beams for local irradiation), laser aiming devices (e.g., red dot sights on toy guns).

2.3.4 Protection Requirements

• Personal protection:

◦ Forbid direct viewing of beams; maintain safe distance (recommended ≥1 m).

◦ Class 3A M: Strictly prohibit observation through telescopes/microscopes; avoid beam reflections (e.g., stay away from mirrored objects).

• Equipment safety:

◦ Must label “Class 3A Laser Hazard – Avoid Direct Viewing.”

◦ Laser pointers must be power-limited (some countries ban sales above Class 3A) and equipped with safety locks (e.g., press-to-activate switches to prevent accidental activation).

2.4 Class 3B: High-Risk Lasers (Including Class 3B M)

2.4.1 Classification Criteria

• Parameter range:

◦ Continuous wave: Visible/non-visible, 0.5 W ≥ P > 5 mW (wavelength-dependent thresholds, e.g., 1064 nm IR allows average power ≤10 W);

◦ Pulsed lasers: Single-pulse energy ≤500 mJ, or average power within the above range;

◦ Class 3B M: Collimated beams; direct viewing is dangerous, while diffuse reflection may be safe (requires energy assessment).

2.4.2 Hazard Characteristics

• Eyes:

◦ Direct/mirror reflection: Instantaneous (<0.25 seconds) permanent retinal damage (visible light) or corneal burns (UV/long-wave IR).

◦ Diffuse reflection: Low energy, generally no retinal damage, but UV/IR diffuse reflection may cause cumulative corneal damage (e.g., long-term 1064 nm IR exposure may lead to lens opacification).

• Skin: Prolonged direct exposure may cause mild thermal burns (erythema, blisters); pulsed lasers may cause punctate burns due to high instantaneous energy.

2.4.3 Typical Applications

• Medical laser scalpels (low-power mode, e.g., excimer lasers for ophthalmology with controlled pulse energy);

• Research medium-power lasers (e.g., 532 nm green lasers for spectroscopy, 10–100 mW);

• Industrial laser marking machines (low-energy mode for metal surface labeling, wavelengths 1064 nm/355 nm).

2.4.4 Protection Requirements

• Personal Protective Equipment (PPE):

◦ Safety goggles: Must wear EN 207/EN 208-compliant laser goggles selected by wavelength (e.g., “OD4+” for visible light, “OD6+” for IR; Class 4 requires custom “OD8+”).

◦ Protective clothing: If skin exposure is possible (open optical paths), wear laser-resistant gloves (aramid/aluminized fabrics) and avoid bare skin facing beams.

• Engineering controls:

◦ Enclosed optical paths or protective shields with interlocks (power cuts when opened).

◦ Designate “hazard zones” with red warning lights and barriers; restrict unauthorized access.

◦ Matte surface treatments to reduce specular reflections; anti-reflective coatings on walls.

• Administrative measures:

◦ Operators must receive professional training and certification.

◦ Regularly calibrate laser power to ensure Class 3B compliance.

◦ Develop emergency plans with eyewash stations, burn kits, and safety procedure posters.

2.5 Class 4: Extremely High-Risk Lasers (Including Class 4 M)

2.5.1 Classification Criteria

• Parameter range:

◦ CW/pulsed lasers: Power > 0.5 W (visible) or >10 W (IR/UV); single-pulse energy >500 mJ;

◦ Class 4 M: Collimated beams pose extreme risk regardless of optical instruments, with diffuse reflection also hazardous.

2.5.2 Hazard Characteristics

• Eyes:

◦ Direct/mirror reflection: Nanosecond-scale pulses can cause retinal perforation and blindness.

◦ Diffuse reflection: Energy may exceed tolerance thresholds (especially visible/mid-IR), with chronic photochemical damage from long-term exposure.

• Skin:

◦ Direct exposure: Instantaneous thermal damage (vaporization, carbonization); pulsed lasers cause deep burns (e.g., 1064 nm high-power laser cutting may splash beams onto skin).

◦ Secondary hazards: May ignite flammables (clothing, paper), posing fire risks.

• Other risks: UV lasers generate ozone (O₃), causing respiratory damage; high-power lasers may interfere with electronics.

2.5.3 Typical Applications

• Industrial laser cutters (1–10 kW, wavelengths 1064 nm/10.6 μm for metal/non-metal cutting);

• High-power medical lasers (e.g., holmium lasers for tumor resection with multi-joule pulse energy);

• Research high-energy laser systems (e.g., laser fusion devices, high-power pulsed lasers);

• Military laser weapons (e.g., shipboard laser cannons ≥100 kW for drone interception).

2.5.4 Protection Requirements (Highest Level)

• Personal protective equipment:

◦ Safety goggles: Labeled “Class 4 Laser Protection,” custom OD values (e.g., OD8+ for 1064 nm, transmission <0.0001%) with impact resistance testing.

◦ Full-body laser-resistant suits (multi-layer flame-retardant/laser-reflective fabrics), protective masks (face/neck coverage), and specialized gloves (balance sensitivity and protection).

◦ Auxiliary equipment: Laser radiation detectors (real-time energy density monitoring), respiratory protection (ozone filters for UV environments).

• Engineering and environmental controls:

◦ Fully enclosed optical paths: Sealed except for necessary beam outlets (e.g., cutting heads with protective shields).

◦ Interlock and monitoring systems:

- Infrared sensors at entrances to cut power when personnel enter.

- Video surveillance and real-time energy monitoring with audio-visual alarms: flashing red lights + buzzers.

◦ Safety distances and barriers: - Dual fencing: Outer warning barrier (≥5 m from equipment), inner secure barrier (authorized access only).

- Floor-marked safe routes to avoid beam reflection paths (e.g., away from shiny floors/metal).

• Administrative and operational protocols:

◦ Personnel qualification: Operators must hold Laser Safety Officer (LSO) certifications and complete 8+ hours of annual retraining.

◦ Operational procedures: - Pre-start checks for PPE integrity (e.g., goggle scratches, suit tears).

- Dual-lock power controls (two-person operation required) and protective covers for laser heads when not in use.

- Maintain logs of laser power, usage time, and operator information.

◦ Emergency response: - Develop Laser Injury Emergency Plans with clear protocols for burns/blindness (e.g., immediate power-off, cold water 冲洗,hospital transport with laser parameter reports).

- Quarterly emergency drills to familiarize personnel with escape routes and first-aid locations (eyewash stations ≤10 m from work areas, clearly marked).

III. Laser Safety Considerations in Special Scenarios

3.1 Special Risks of Pulsed Lasers

Pulsed laser hazards depend not only on average power but critically on single-pulse energy and peak power. For example, a 10 Hz pulsed laser with 100 mJ single-pulse energy has an average power of 1 W (Class 3B) but a peak power of 10 kW (if pulse width = 10 ns), with instantaneous energy sufficient to penetrate the retina. Thus, pulsed laser classification requires evaluating both average power and single-pulse energy, with protections against “instant high-energy” risks (e.g., nanosecond-level optical shutters, no bare-hand operation of pulse laser heads).

3.2 Differentiated Hazards of UV and Infrared Lasers

• Ultraviolet lasers (λ<400 nm):**

◦ Hazard mechanism: Primarily damage cornea/lens, causing “electro-optical keratitis” (corneal epithelial necrosis, symptoms: severe pain, photophobia, tearing, 24–48 hour recovery) and cataracts (long-term lens opacification).

◦ Protection priorities: Wear UV-specific goggles (OD5+ for 266 nm), avoid skin exposure (UV-induced photosensitive dermatitis).

• **Infrared lasers (λ>700 nm):

◦ Mid-infrared (700 nm<λ≤1400 nm): Penetrates cornea, absorbed by lens, causing protein denaturation and “infrared cataracts” (latency: years–decades).

◦ Long-wave infrared (λ>1400 nm): Absorbed by cornea/skin, causing thermal damage (corneal opacification, skin carbonization).

◦ Protection priorities: Mid-IR requires yttrium oxide (Y₂O₃)/zinc sulfide (ZnS) goggles; long-wave IR needs silicon/germanium-based goggles, plus full skin coverage (long sleeves, gloves).

3.3 Beam Divergence and the Essence of M-Class Classification

The core risk of M-class (“Mobile”) lasers lies in beam collimation. For example, Class 1M lasers have small divergence angles (e.g., lidar collimated beams), with low pupil energy during direct viewing (Class 1 safe). However, telescope observation focuses the beam, potentially increasing pupil energy by hundreds of times (upgrading to Class 3B risk). Thus, M-class classification fundamentally addresses “optical instrument magnification risks,” with protections focusing on banning optical device use and explicit warnings in manuals.

IV. International Regulations and Practical Cases in Laser Safety

4.1 Laser Product Regulation in Major Jurisdictions

• EU: Based on IEC 60825-1, laser products require CE certification. Class 3B+ devices are banned from public sale (except professional use). Laser pointer power is limited to ≤1 mW (Class 2), with fines up to €100,000 for violations.

• USA: FDA’s CDRH standard mandates “DANGER LASER RADIATION” labels for Class 4 devices. Unapproved medical cosmetic use (e.g., Class 4 laser 脱毛 by unlicensed clinics) may face criminal penalties.

• China: GB 7247.1-2012 (equivalent to IEC) requires production licenses for Class 3A+ laser pointers and bans high-power laser pointer sales to minors.

4.2 Typical Accidents and Protection Improvements

Case 2: Industrial Laser Cutting Burn (2024)

A factory worker suffered blindness in the left eye due to accidental reflection from a Class 4 laser because they were not wearing protective goggles.

Improvements: Install beam path sensors that automatically activate shutters when personnel enter danger zones. Mandate the use of augmented reality (AR) smart goggles that provide real-time alerts of beam positions with flashing warnings.

Case 1: Laser Pointer Blindness Incident (2023)

A child used a mislabeled Class 2 laser pointer, which had an actual power of 50 mW (classified as Class 3B), to shine into their eye. This resulted in permanent macular damage and a vision loss of 0.1.

Improvements: Strengthen market supervision by enforcing mandatory power labeling and implementing built-in power monitors (with auto-shutoff for power exceeding 1 mW). Additionally, promote parental education on laser classification.

V. Future Trends: Innovations and Challenges in Laser Safety Technology

5.1 Safety Assessment of New Laser Technologies

As ultrafast lasers (femtosecond/picosecond), high-power fiber lasers, and UV LED lasers become more widespread, traditional classification standards are facing new challenges. For instance, femtosecond lasers, which operate at ultra-high peak powers (in the terawatt range) but have extremely short pulse widths (less than 100 femtoseconds), alter the damage mechanisms from “thermal” effects to “photoionization-induced plasma disruption.” This shift necessitates the development of new exposure threshold models.

5.2 Development of Intelligent Protection Technologies

VR Simulation Training: Virtual reality scenarios, like the Meta-3M laser safety courses, simulate exposure risks to enhance operators’ emergency response capabilities.

Real-time Monitoring Systems: AI-powered laser sensors continuously calculate energy density and automatically adjust cutting power when thresholds are exceeded. For example, Huawei’s laser safety IoT system has a response time of less than 10 milliseconds.

Adaptive Protective Gear: Smart goggles equipped with dynamic light-adjusting filters, such as those using Liquid Crystal Technology, eliminate the need for frequent model changes.

5.3 Enhancing Public Safety Awareness

Future initiatives should focus on improving laser safety education, which includes the following strategies:

Advocate for “risk-free design” principles for consumer lasers, such as projectors and toys, by adhering to Class 1/2 safety standards as the default.

Integrate the basics of laser classification into K-12 curricula, utilizing animations to effectively demonstrate hazards across different subjects.

Establish national platforms for laser safety reporting to encourage the public to report illegal sales of high-power laser pointers.

Conclusion

The laser classification system is fundamental for ensuring safe laser use, providing “precision protection” through scientific risk assessment. This system categorizes lasers from Class 1, where “no protection is needed,” to Class 4, which requires “total isolation.” Each class is based on strict technical parameters and guidelines.

For professionals, understanding how these classifications work and the appropriate protection protocols is crucial for preventing occupational hazards. Meanwhile, the public must recognize safety classes and avoid high-risk devices to ensure their personal safety.

As technology continues to evolve, laser safety measures will also advance. However, the principle of “safety first” remains constant. By implementing classification standards into everyday practices, we can make lasers truly a “safe light” for driving societal progress.

References

- IEC 60825-1:2014, Safety of Laser Products – Part 1: Equipment Classification and Requirements

- 21 CFR Part 1040.10, Performance Standards for Light-Emitting Products

- GB 7247.1-2012, Safety of Laser Products – Part 1: Equipment Classification, Requirements

- International Laser Safety Association (ILSA) Guidelines, Laser Safety Handbook

- American National Standards Institute (ANSI) Z136.1-2020, Safe Use of Lasers